Rocket Fuel Grains and Nozzle

c. 2015

Thermodynamics

Nicholas Akiona, Brian Holman, Aaron Oro, Jamie Young

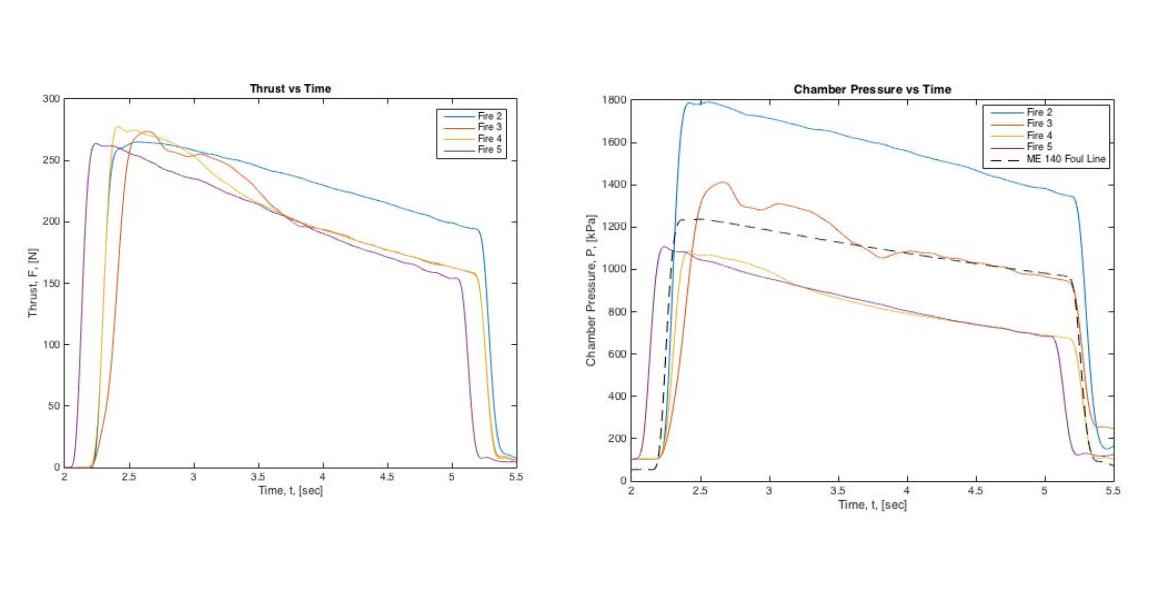

For Stanford’s capstone Thermoscience course in Mechanical Engineering, ME 140, we were tasked with designing and manufacturing fuel grains and a nozzle for hybrid rockets fires. The ultimate goal was to maximize specific impulse while maintaining a chamber pressure of less than 1.1 MPa.

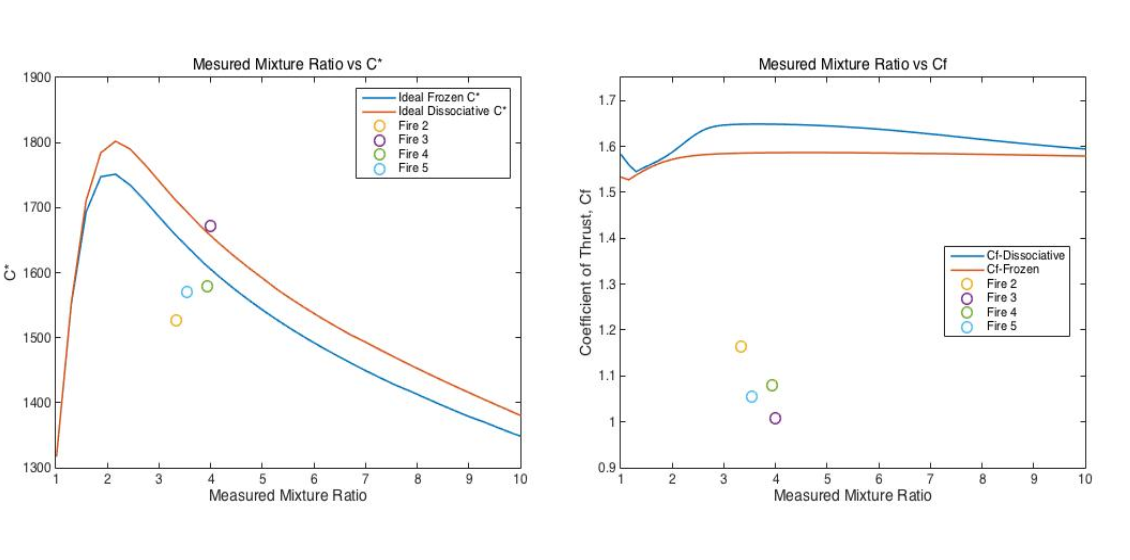

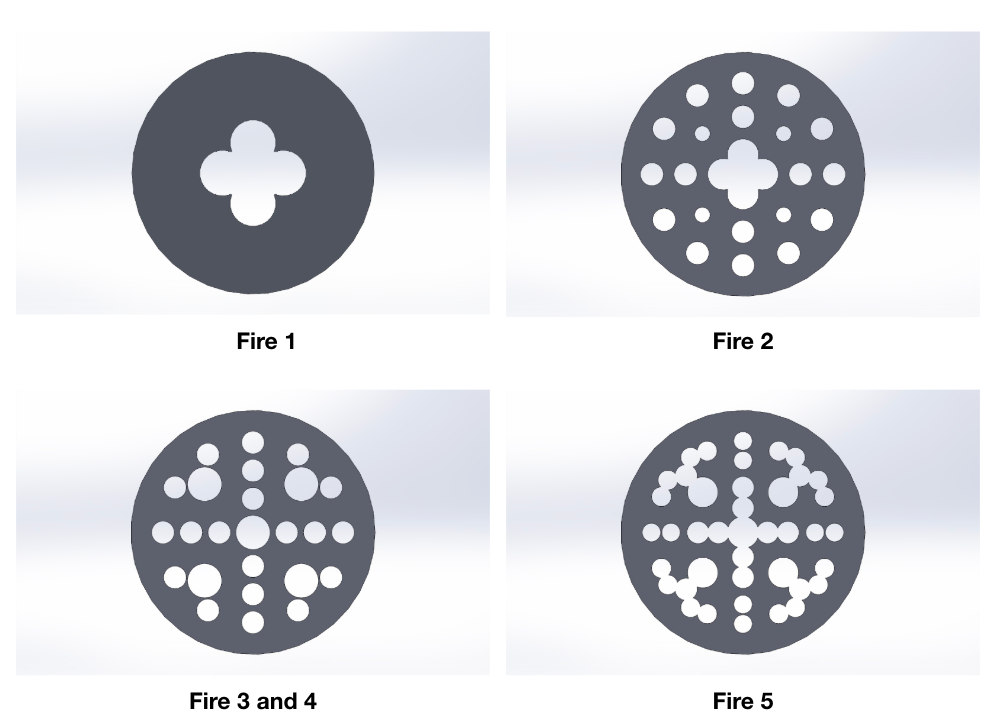

Our group decided to optimize for a linear, neutral-to-regressive burn rate with a target mixture ratio of 3. Additionally, we developed a fuel regression model to aid with fuel grain design. This allowed us to visualize how a grain would burn before a fire. Ultimately our best fire, shown to the right, yielded a specific impulse of 174.6 s, good enough for second in the class. Furthermore, this fire yielded a mixture ratio of 4 and a chamber pressure of .99 MPa. For more in depth discussion of analysis and results, see the report linked below.

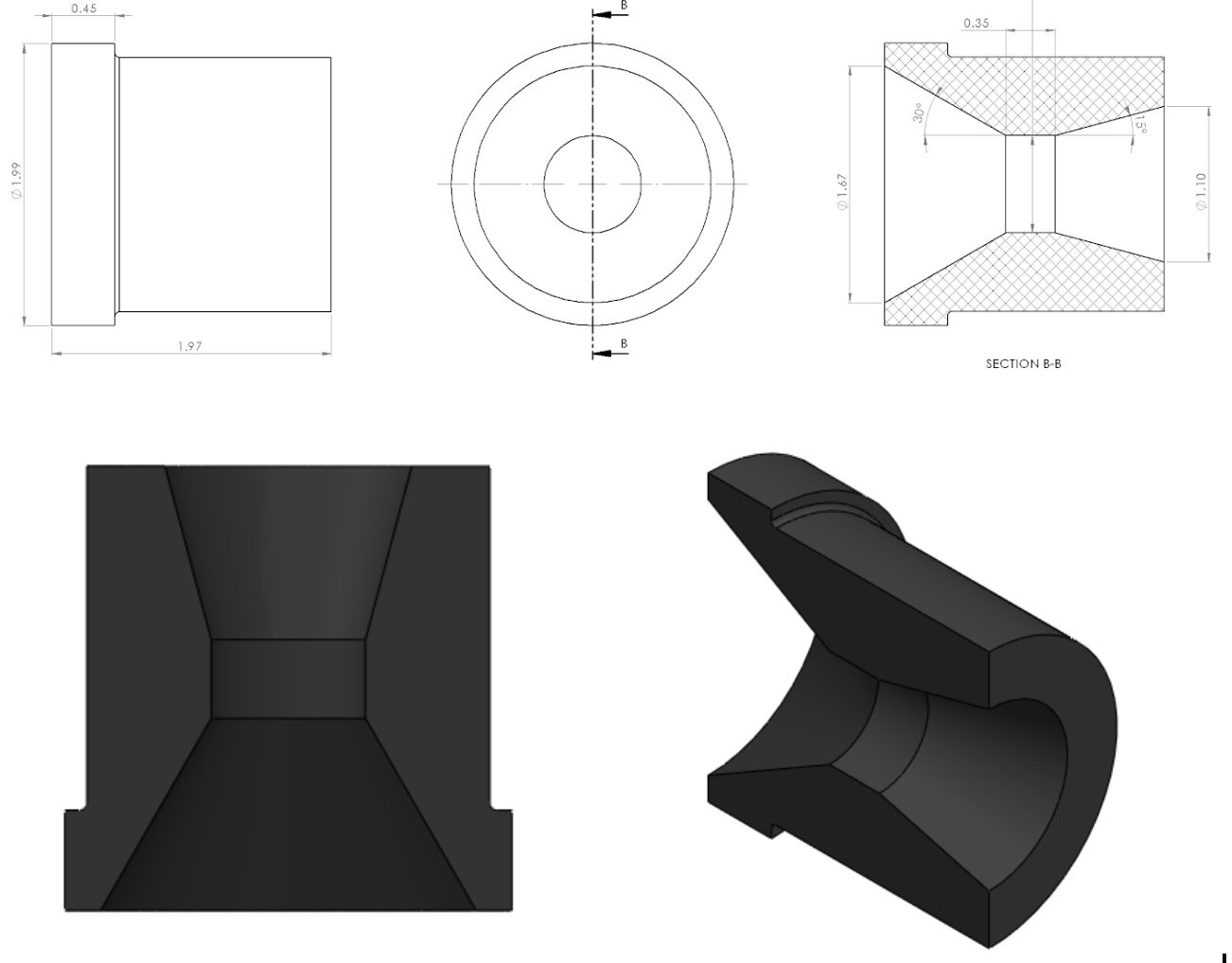

Note that the nozzle was machined out of graphite on a manual lathe, and the fuel grains were machined out of HDPE on a manual lathe and mill. Both were governed by strict dimensional tolerances. Ultimately, we machined and tested 5 different fuel grain designs with a single nozzle.

Fuel Grain 4 fire result

For more information, please see the full Rocket Report linked below.