Kinematic LAser mount

c. 2018

Precision Engineering

Bethany Chaffin, Ian Sparkman, Keven Wang, Jamie Young

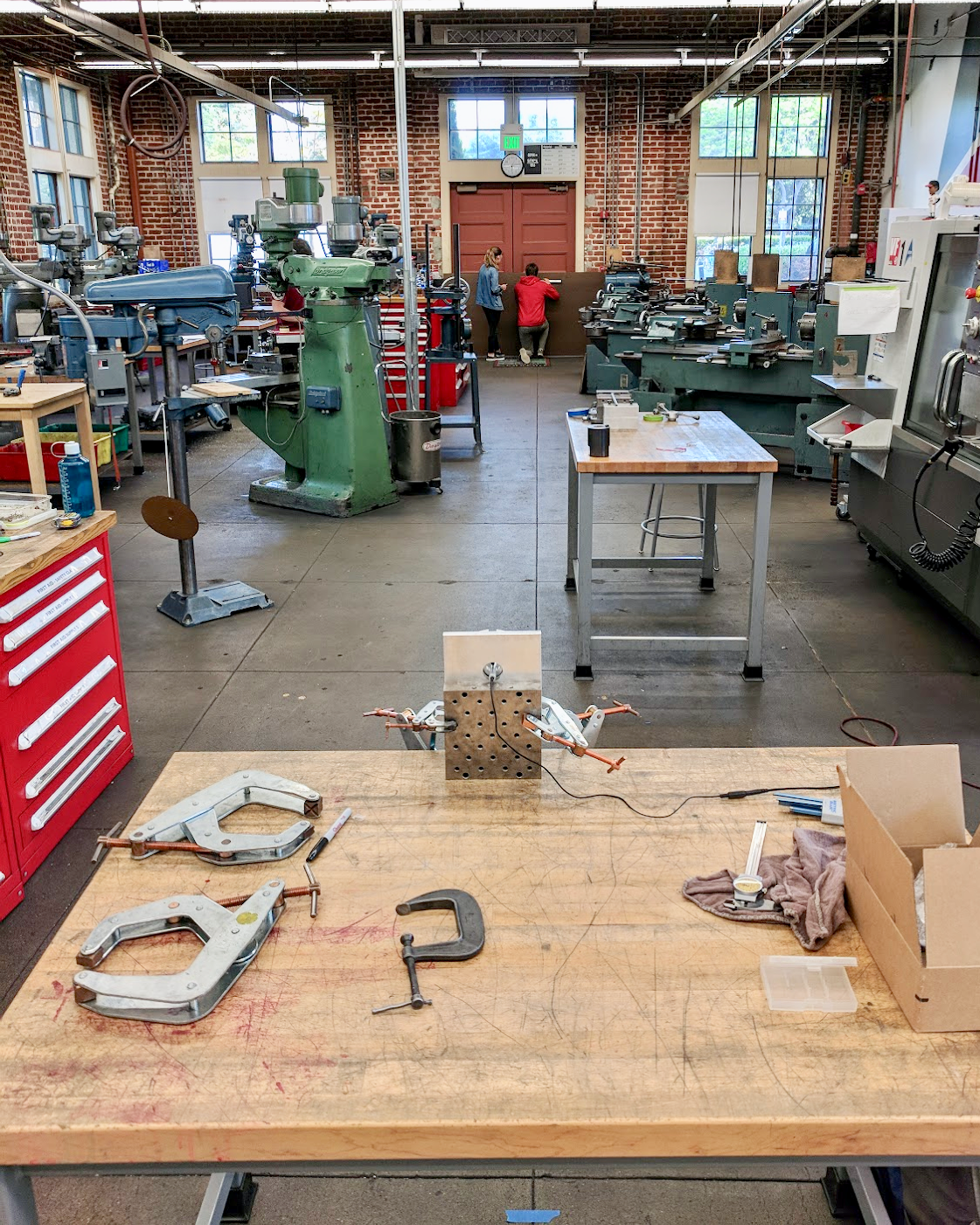

For Stanford’s ME 324, we were tasked with designing and building a kinematic laser mount that allowed for calibration around one rotational axis. Furthermore, the design objective was to ensure repeatability between mountings of both the laser and the front plate of the mount.

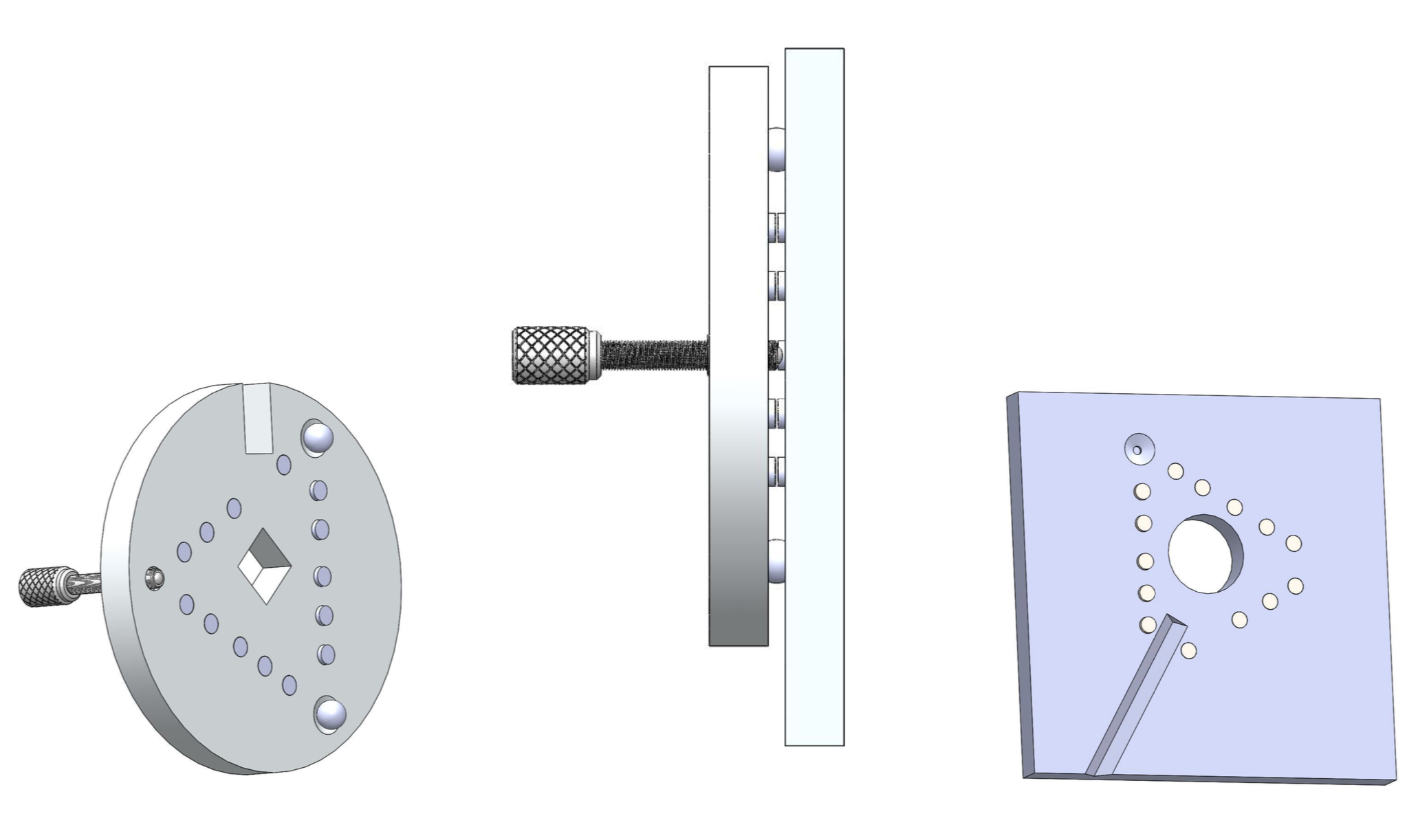

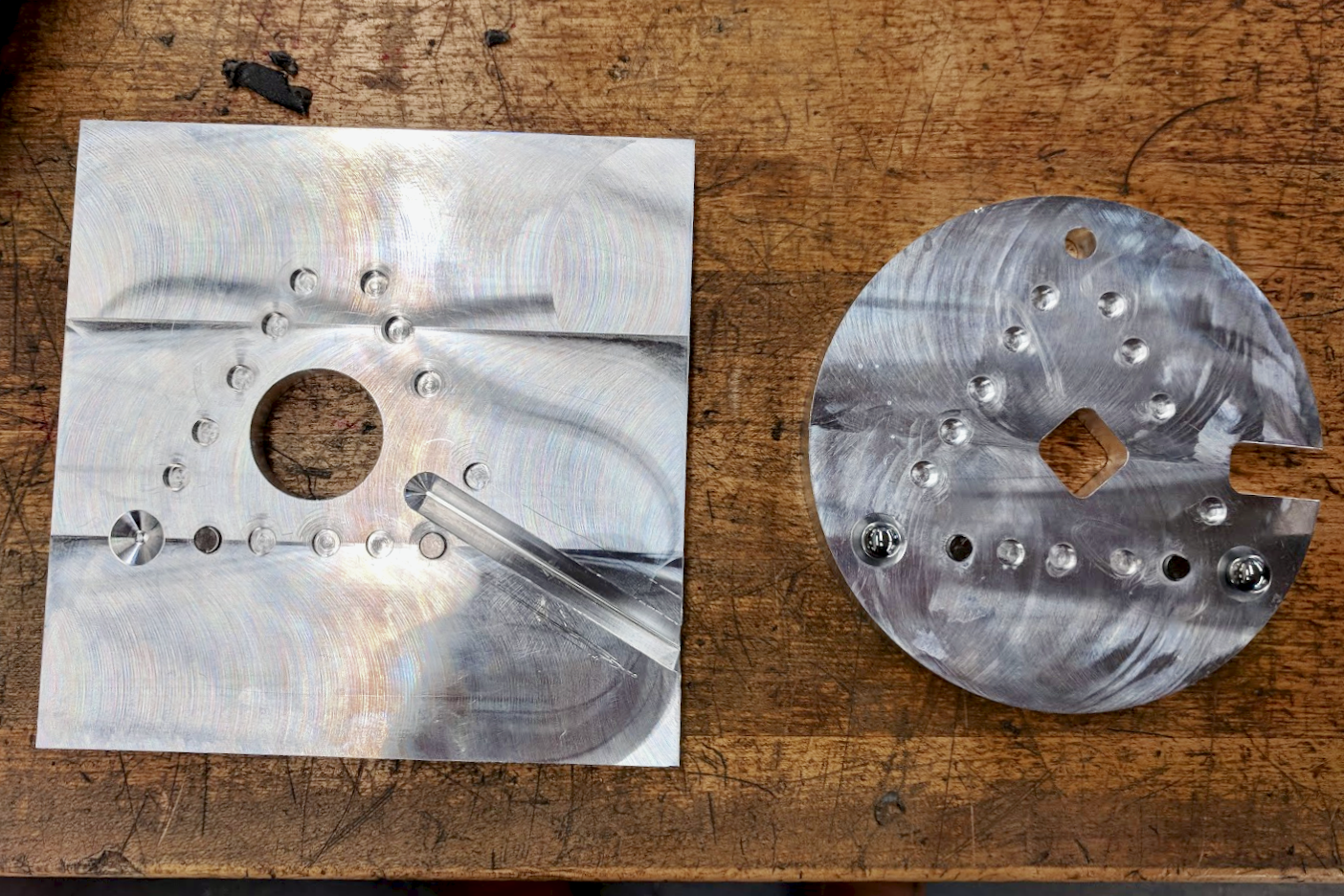

Our group decided to employ a modified Kelvin clamp design incorporating a fixed back plate and a front circular plate with one adjustable rotational DOF controlled by a fine thread ball end adjustment screw. Machined into the fixed plate was a cone (approximation for a trihedral pocket), a vee groove, and a flat surface that mated, respectively, with two steel precision ball bearings and the fine thread ball end adjustment screw. Magnets at the bottom of machined conical pockets in the front plate held the ball bearings in place. Furthermore, magnets embedded in both plates along the axis of rotation allowed for simple attachment and detachment of the two plates. Finally, the laser was constrained in a vee groove in the circular plate by a separate ball end set screw.

By adjusting the fine thread adjustment screw, our mount allowed for 7.37 degrees of rotation, with a minimum repeatable resolution of .0576 degrees. Furthermore, when mounting and un-mounting the front plate of the mount, no perceptible difference in laser position was detected at a distance 4.78m.

For more information, please see the full Kinematic Laser Mount Report linked below.