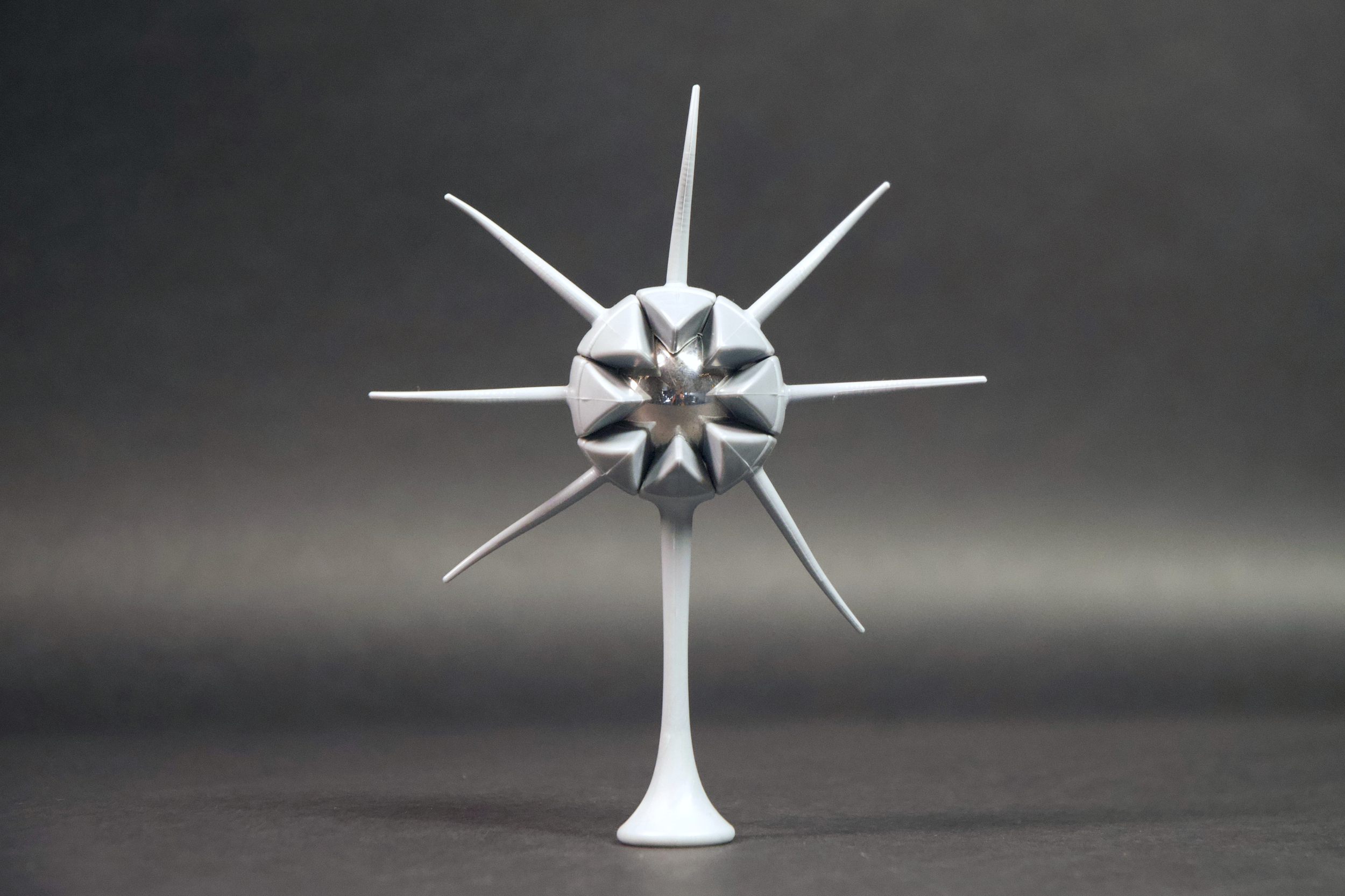

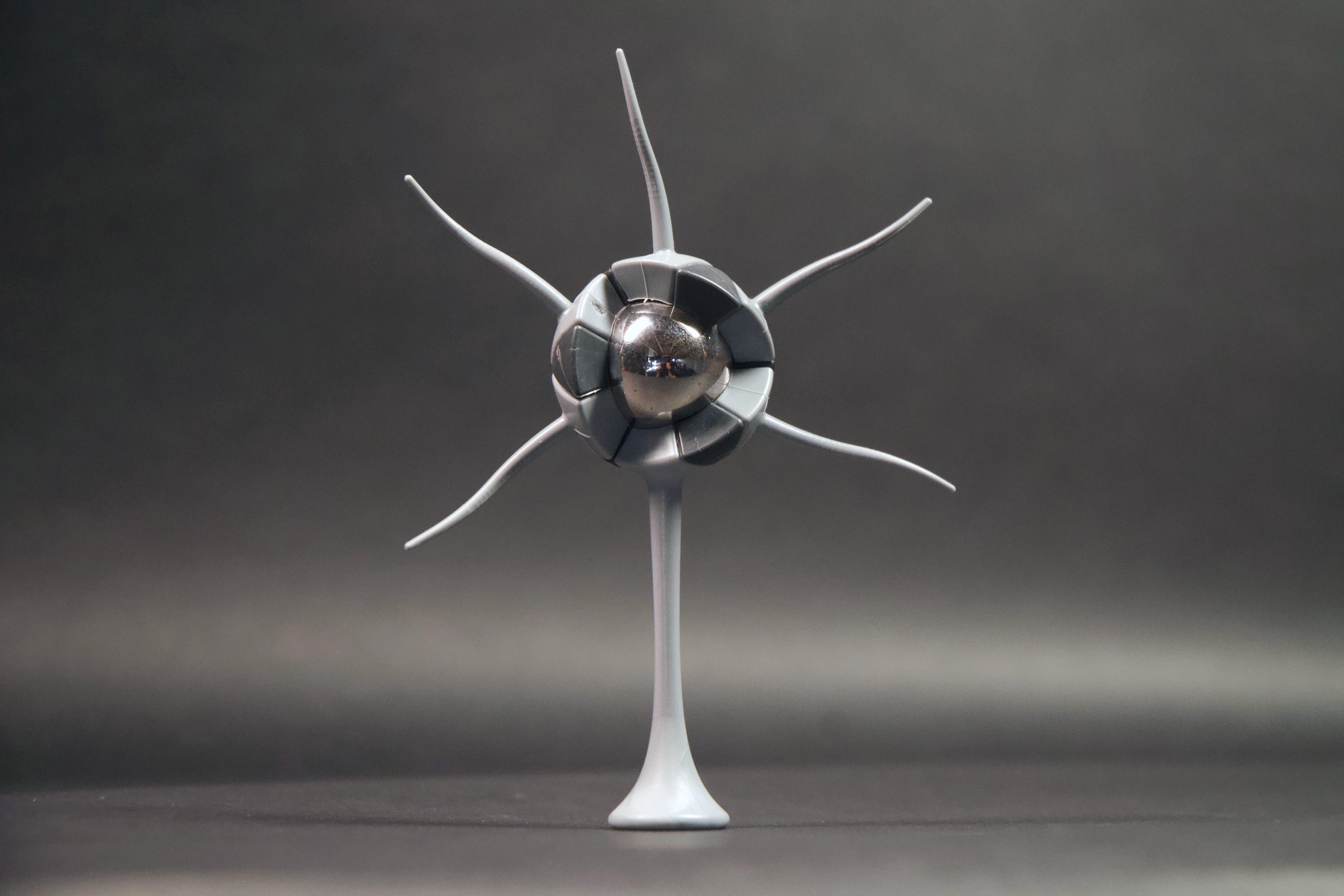

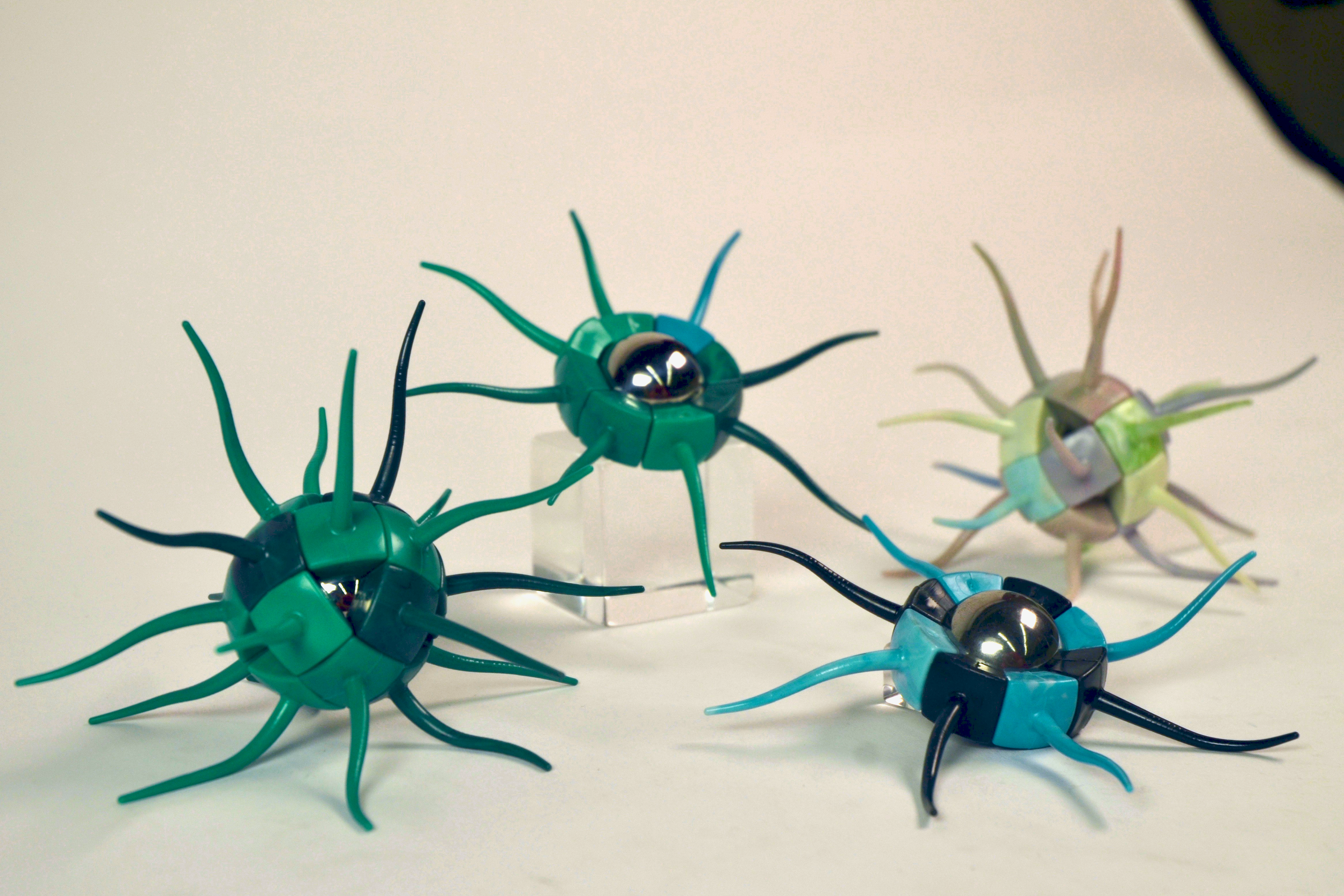

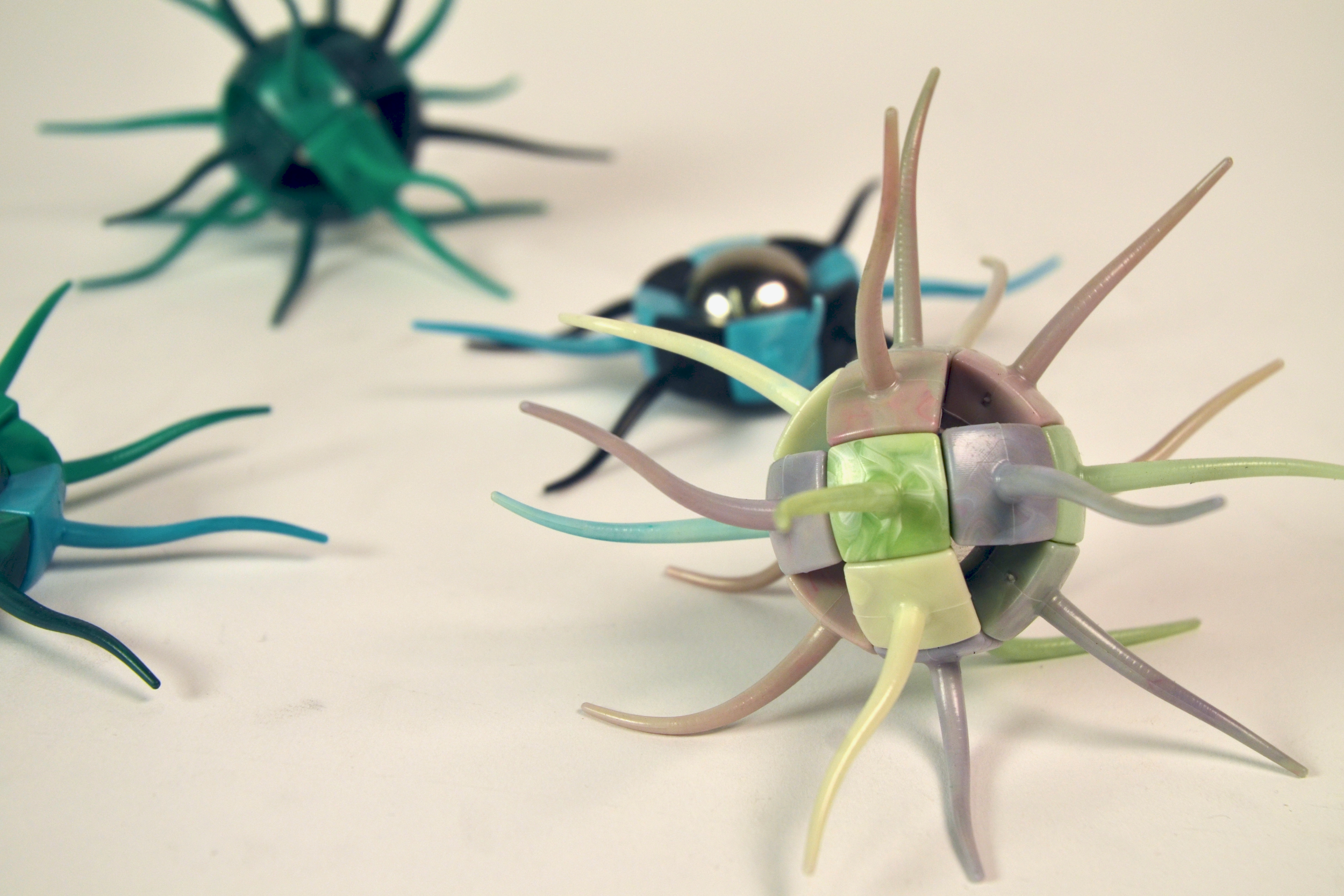

Hedron Assembly

c. 2017

HDPE, Dynaflex, Low-Carbon Steel, Neodymium Magnets, Walnut

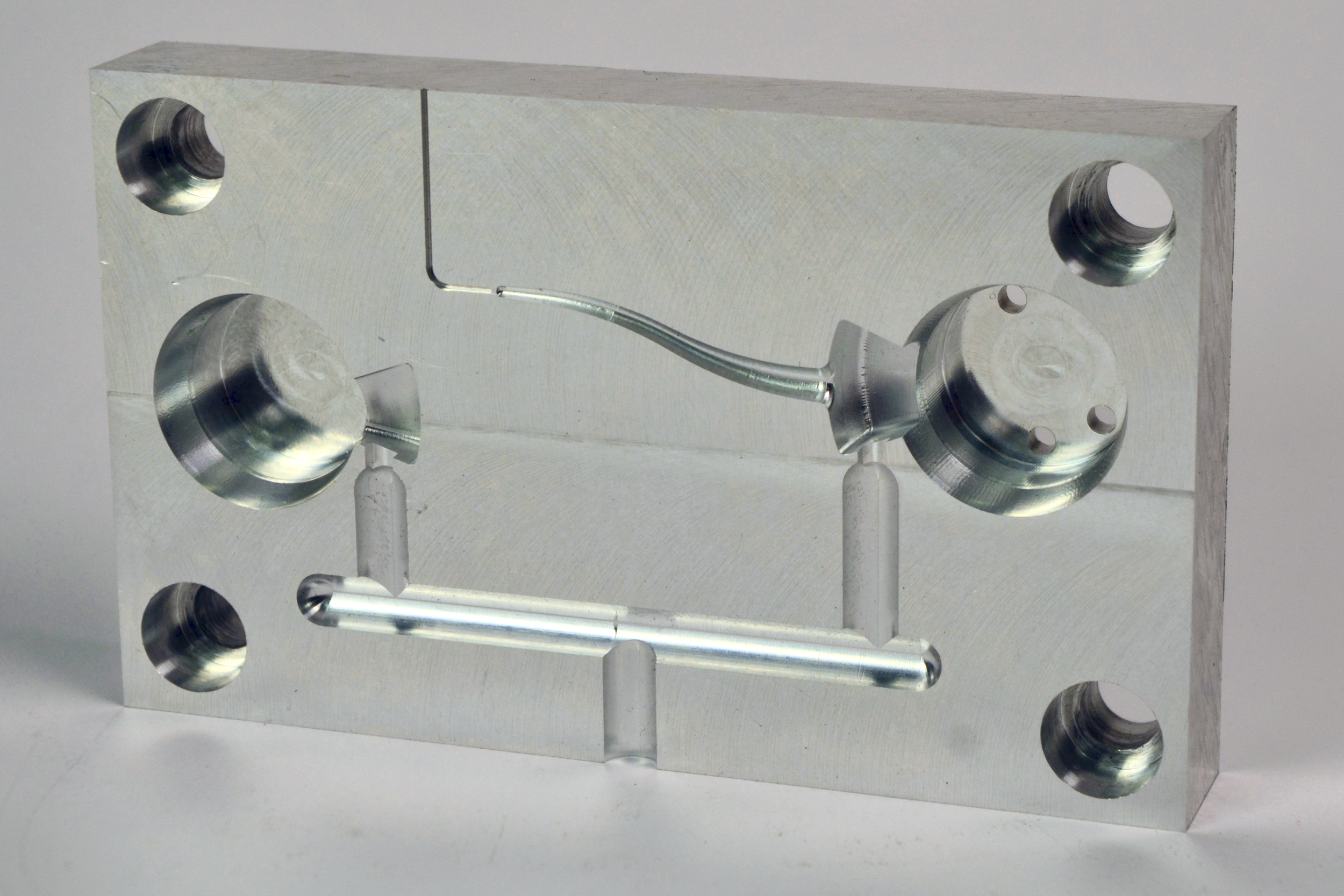

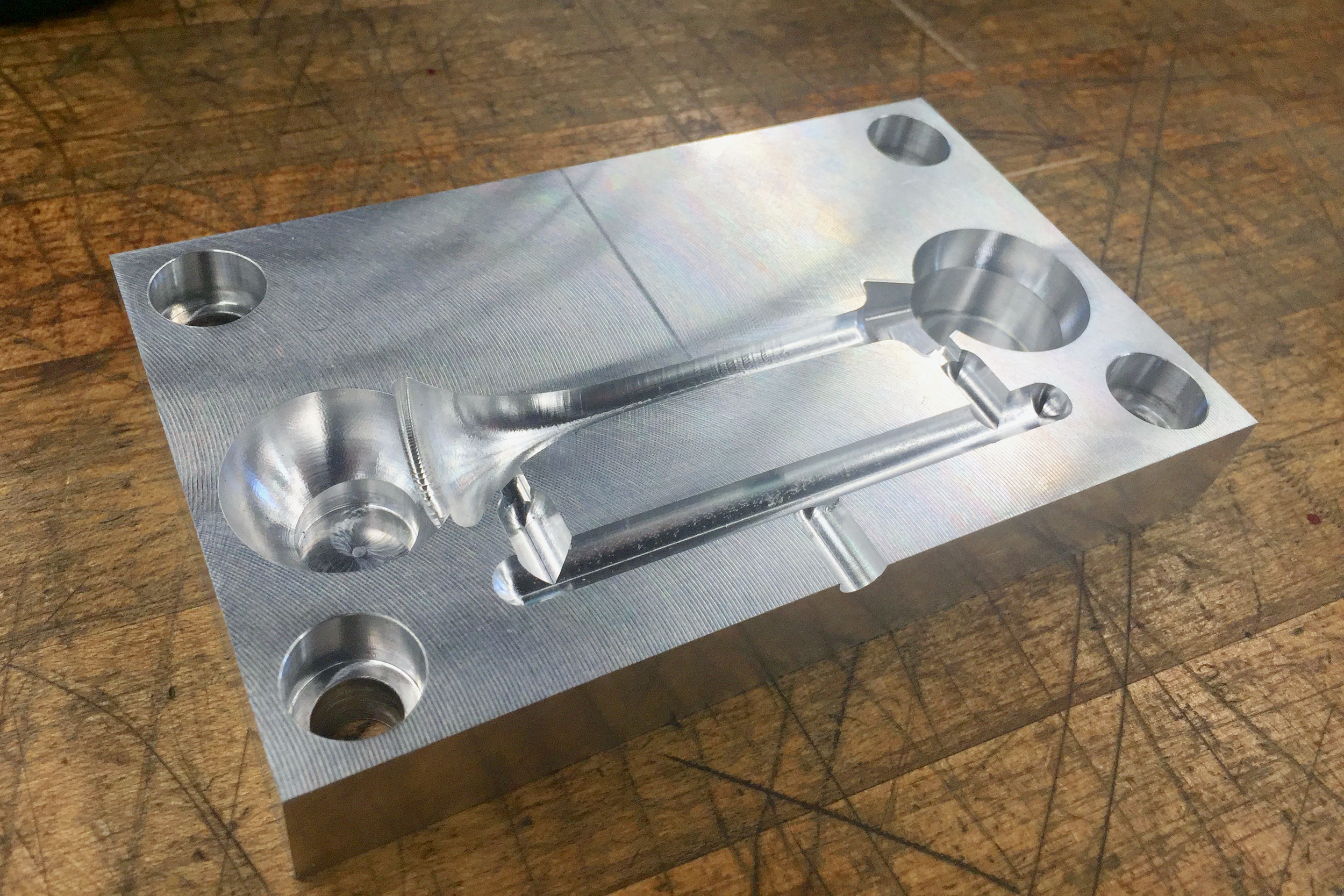

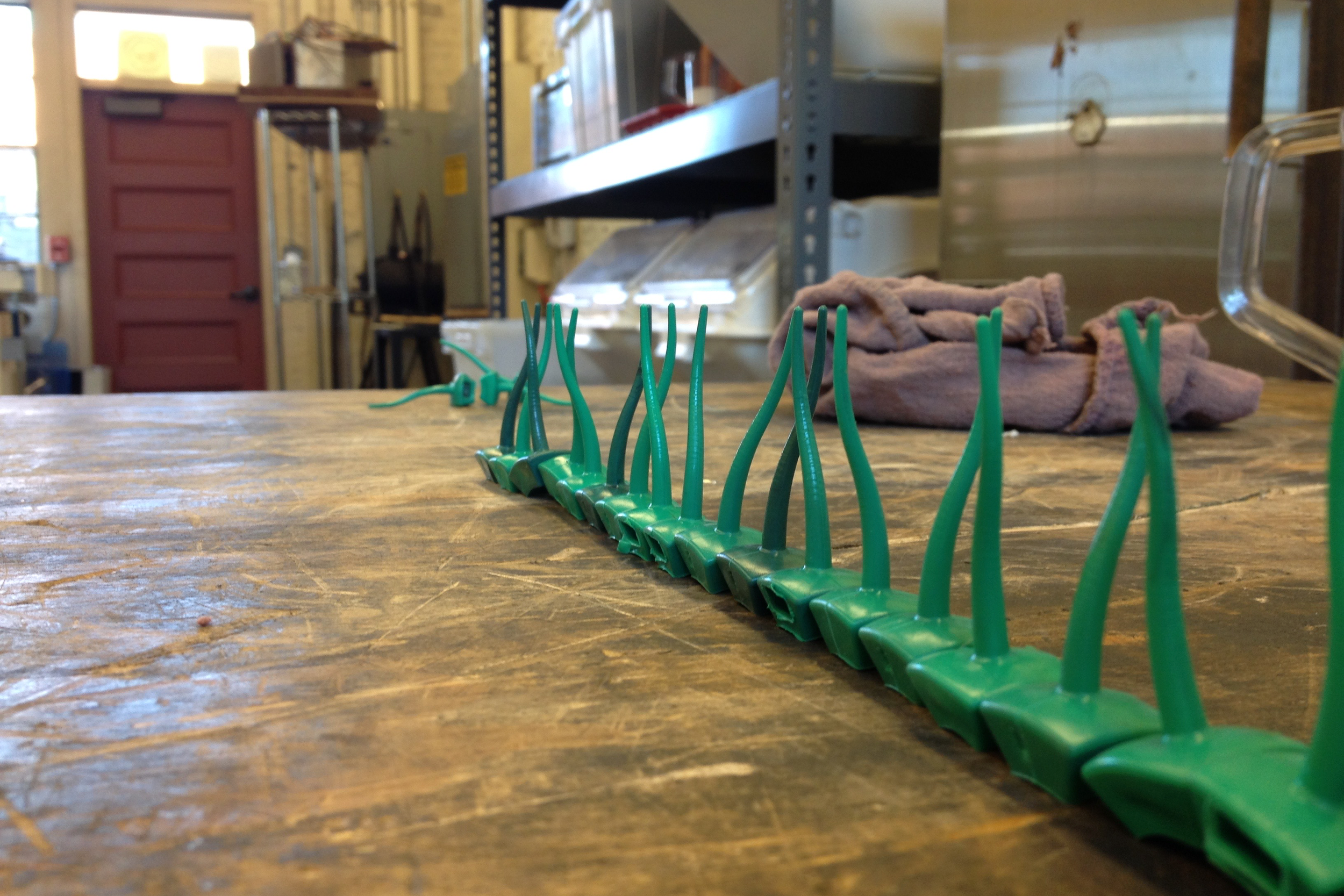

Injection Molding, CNC Milling, Woodworking

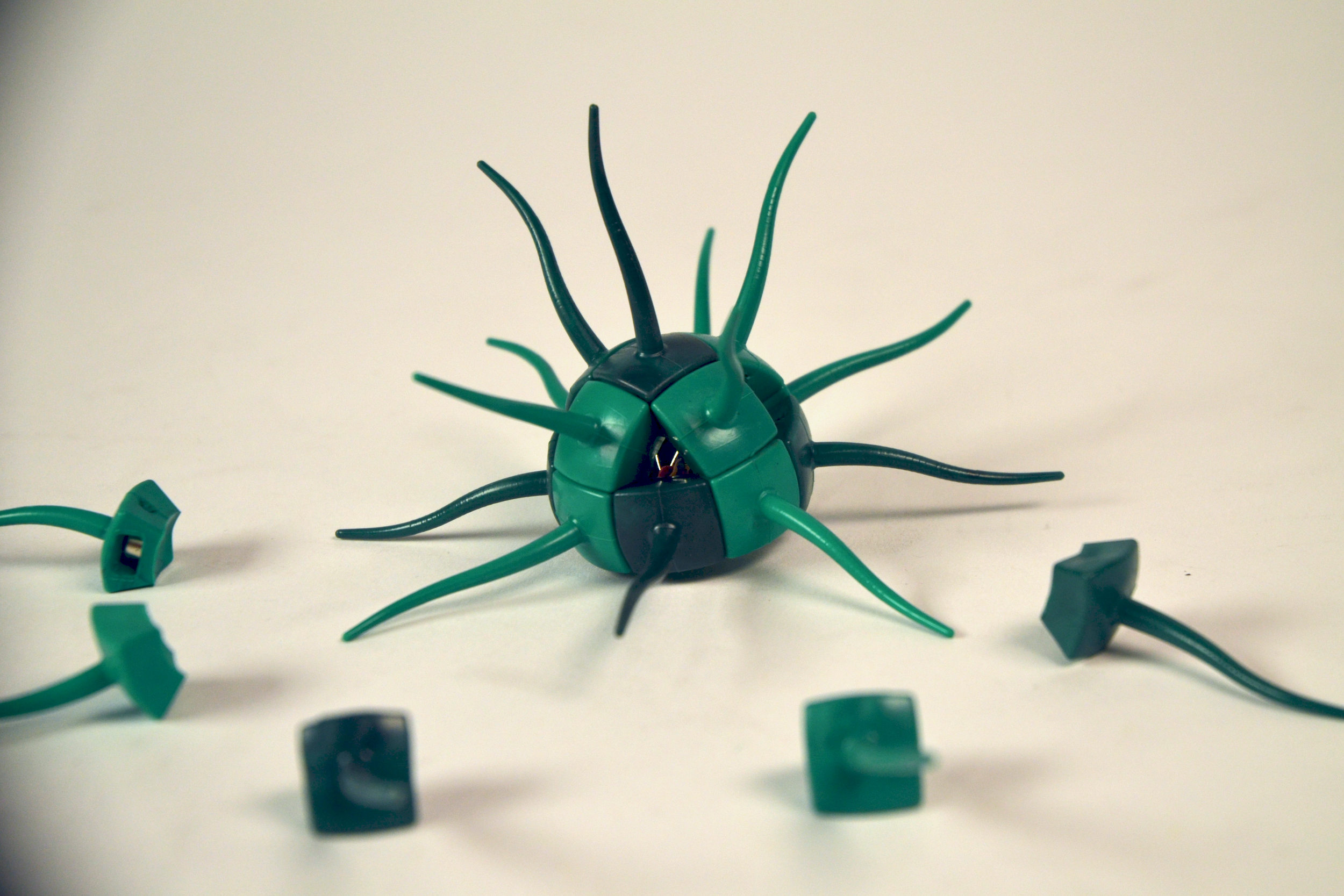

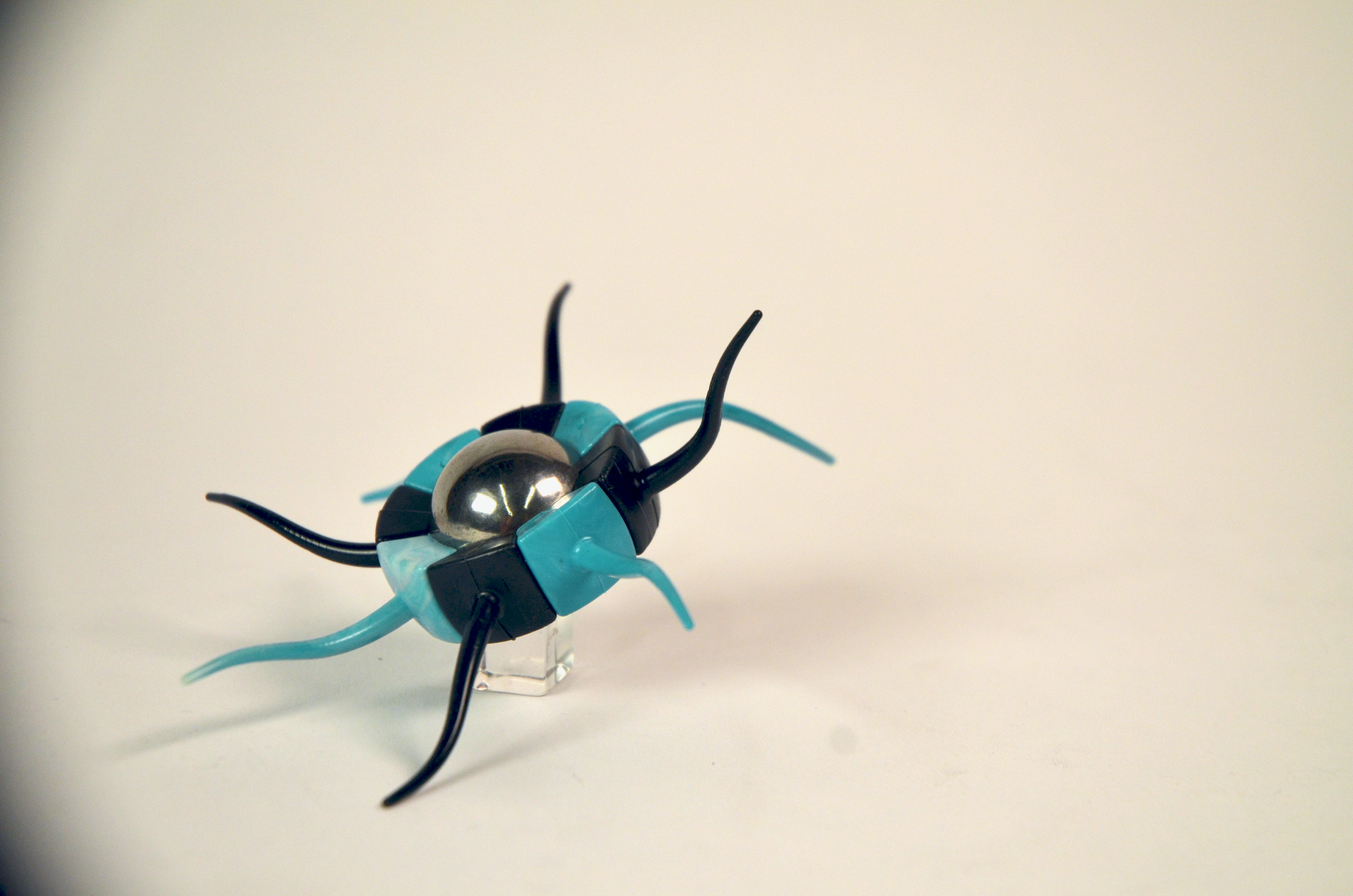

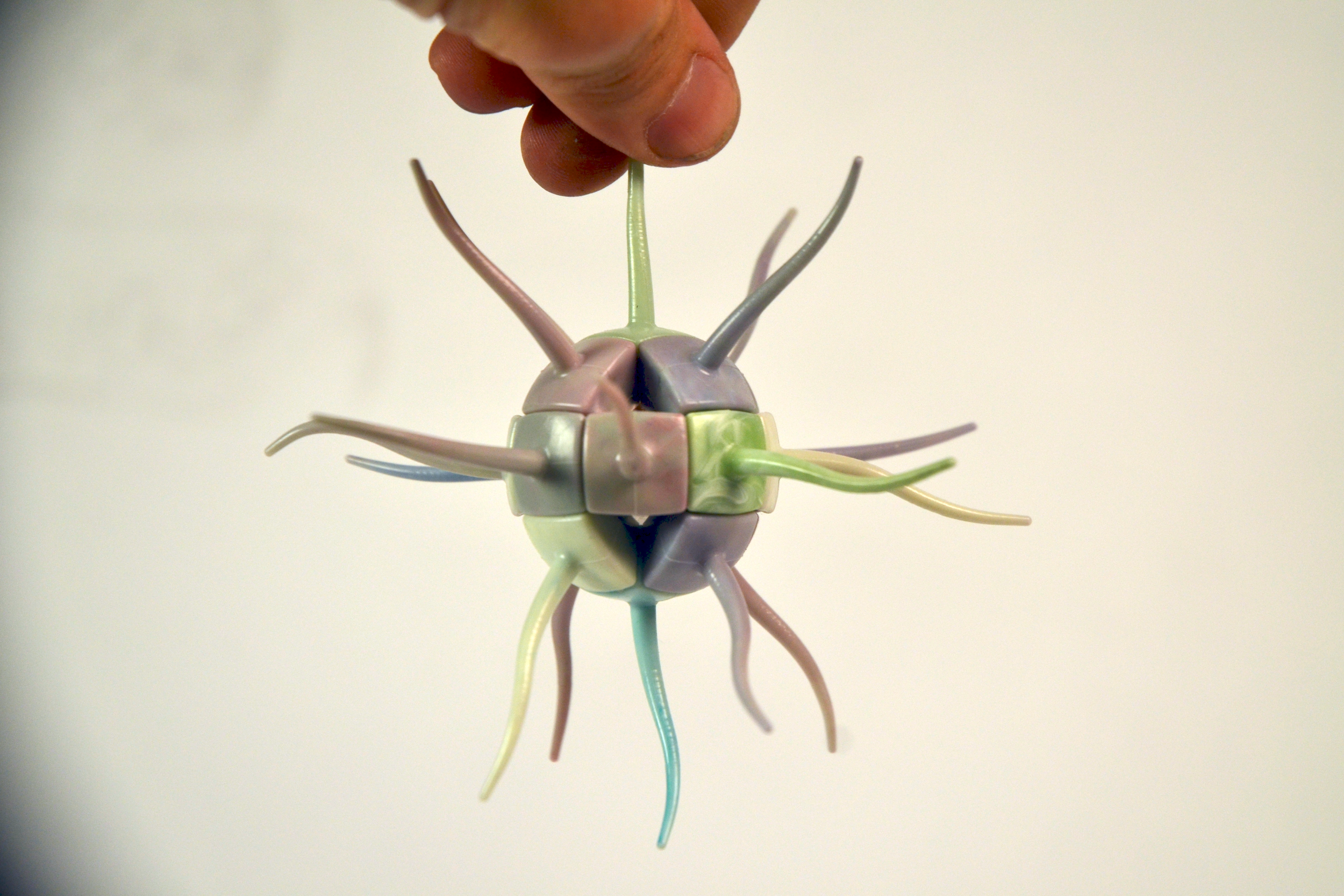

Early Iterations and Tooling

This sculptural project plays off the concept of manipulating a few unit parts to create a number of unique forms. Using a rhombicuboctahedron as a parent form, three parts [a stand, a tentacular unit square, and a basic unit triangle] allowed for the creation of the displayed models. The parts were injection molded in grayscale using aluminum tooling machined on a CNC mill. To aid assembly, cores were added to the tooling to create small pockets in one side of the stands and unit squares. Magnets were then added in these pockets, allowing the parts to be attached to steel spheres in a variety of orientations and combinations.